The difference between instant and slow-dissolving hydroxypropyl methylcellulose (HPMC)

introduce:

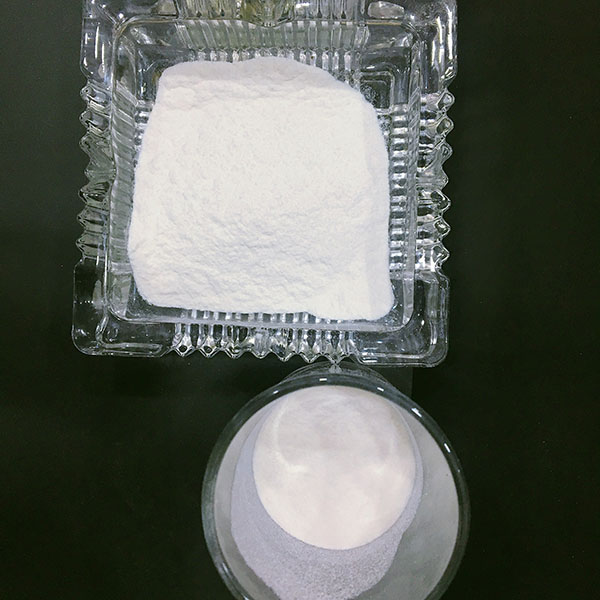

Hydroxypropylmethylcellulose (HPMC) is a versatile polymer derived from cellulose, a natural polymer found in plant cell walls. Due to its unique properties, it is widely used in various industries such as pharmaceuticals, food, construction and cosmetics. HPMC is known for its ability to adjust viscosity, improve adhesion and act as a film former. Two common types of HPMC are instant HPMC and slow-dissolving HPMC, each with different properties and applications.

1. Ingredients and manufacturing:

Both instant-soluble and slow-soluble HPMC are synthesized from cellulose through a series of chemical modifications. The main differences lie in the manufacturing process and the degree of substitution of hydroxypropyl and methoxy groups.

Instant HPMC: This type undergoes additional processing steps to achieve a higher degree of substitution. A higher degree of substitution increases solubility, resulting in faster dissolution in water. The production of instant HPMC requires careful control of reaction conditions to achieve the desired degree of substitution.

Slow-dissolving HPMC: In contrast, slow-dissolving HPMC has a lower degree of substitution. This modification makes the polymer less soluble, resulting in slower dissolution in water. Tune the manufacturing process to achieve a balance between desired performance and intended application.

2. Solubility:

One of the main differences between fast-dissolving HPMC and slow-dissolving HPMC is their solubility characteristics.

Instant HPMC: Exhibits high solubility in water, resulting in rapid dissolution. This property is advantageous in applications requiring rapid release or dispersion, such as fast-dissolving formulations, fast-dissolving tablets, or fast-dispersing powders.

Slow-dissolving HPMC: has low solubility, resulting in slow and sustained release of the polymer in water. This property is beneficial for applications requiring extended release or controlled dispersion, such as sustained-release pharmaceutical formulations or long-lasting construction materials.

3. Application:

The choice between instant and slow-dissolving HPMC depends on the specific requirements of the intended application.

Instant HPMC application:

Pharmaceuticals: Instant HPMC is often used in the formulation of instant tablets and oral films.

Food industry: It is used in instant foods that require rapid dissolution.

Personal care products: Used in instant formulas such as instant masks or cleansing products.

Slow Dissolving HPMC Applications:

Pharmaceutical: Sustained-dissolving HPMC is suitable for sustained-release drug delivery systems.

Construction Industry: Used in mortar and cement formulations to control hydration and improve long-term workability.

Food Industry: For products requiring slow release, such as controlled release food supplements.

4. Release introduction:

Instant HPMC: Has burst release properties due to its rapid dissolution in water. This is advantageous in applications requiring immediate action or dispersion.

Slow Dissolving HPMC: Provides a sustained or controlled release profile that gradually releases the active ingredient over time. This is beneficial for applications that require extended effects or extended performance.

5. Precautions for formula:

Rapidly dissolving HPMC: Formulations containing rapidly dissolving HPMC may require careful consideration of factors such as dosing accuracy and rapid release potential, especially in pharmaceutical products.

Slowly dissolving HPMC: Formulations containing slowly dissolving HPMC can provide greater flexibility in dosing and are suitable for products requiring a more gradual release of the active ingredient.

6. Stability:

Instant HPMC: Although highly soluble, instant HPMC formulations may be more susceptible to stability-related issues, especially in environments with changing humidity levels.

Slow-dissolving HPMC: Due to its lower solubility and higher stability, it is suitable for applications requiring extended shelf life.

in conclusion:

In summary, the choice between fast-dissolving HPMC and slow-dissolving HPMC depends on the specific requirements of the intended application. Fast-dissolving HPMC is favored when rapid dissolution is critical, such as in rapid-release pharmaceuticals or ready-to-eat foods. Slowly dissolving HPMC, on the other hand, is selected for applications requiring sustained release or extended performance, such as sustained release pharmaceutical formulations or construction materials. Understanding the properties and characteristics of each type of HPMC is critical for formulators to make informed decisions regarding the desired properties of the final product.