Industrial applications of CMC

This is a common problem in the paint and coatings industry. The settling of pigments in paint can cause uneven color and affect the smoothness and durability of the paint film. The function of CMC is to form a barrier between pigment particles, preventing them from settling. CMC has a high affinity for water, which helps keep pigments dispersed in the paint film.

emulsifier

It helps stabilize oil-in-water emulsions by reducing the interfacial tension between the two liquids. CMC forms a protective layer around the oil droplets, preventing them from coalescing. This makes the emulsion more stable and prevents separation.

Dispersant

Dispersants are chemicals that help disperse solid particles in a liquid medium. CMC is used as a dispersant in the textile industry to improve the dyeing process. It helps disperse the dye particles evenly throughout the fabric, producing uniform color.

Leveling agent

They help reduce the surface tension of the paint, resulting in a smoother, more uniform surface. It helps improve paint flow and leveling, resulting in a more even, attractive paint film.

Adhesive

Adhesives are compounds that help two surfaces stick together.Adding it to adhesive formulations improves the adhesive’s cohesion and bonding properties. CMC helps enhance the bond strength and durability of adhesives.

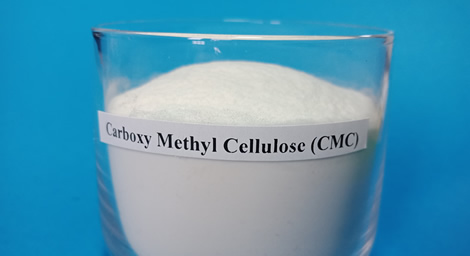

CMC is a multifunctional compound with numerous industrial applications. Used as anti-settling agent, emulsifier, dispersant, leveling agent, adhesive, etc. in different industries. The use of CMC in these industries can improve product quality, increase efficiency, and reduce costs. CMC has the advantages of good stability, low toxicity, and ease of use, making it a popular choice in the chemical industry.