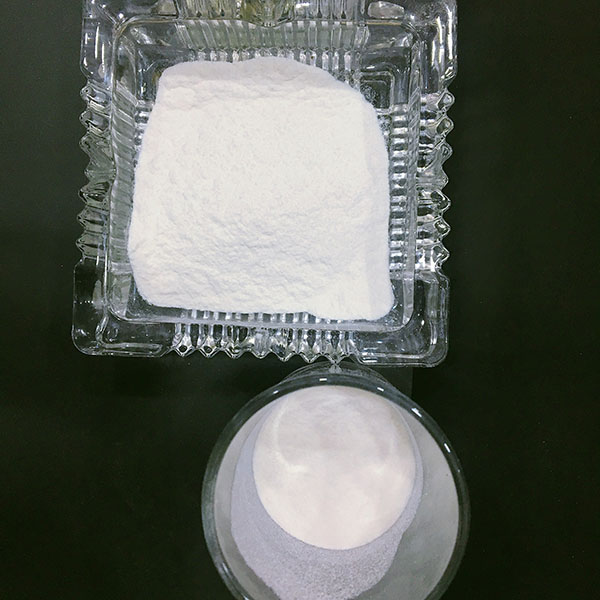

Hydroxypropyl methylcellulose (HPMC) is an ingredient in tile adhesives

Hydroxypropyl methylcellulose (HPMC) is a key ingredient in a variety of building materials, including tile adhesives. This multifunctional compound plays a vital role in enhancing the performance and characteristics of these adhesives, contributing to their effectiveness in bonding tiles to a variety of surfaces.

1. Introduction to hydroxypropyl methylcellulose:

Hydroxypropyl methylcellulose, commonly known as HPMC, is a derivative of cellulose. Cellulose is a natural polymer found in plant cell walls. HPMC is synthesized by modifying cellulose through a chemical reaction, producing a water-soluble polymer with unique properties. This modification involves the introduction of hydroxypropyl and methyl groups into the cellulose structure.

2. Characteristics of HPMC:

Water solubility:

HPMC is highly soluble in water, forming a clear, viscous solution. This property is advantageous in tile adhesive formulations as it facilitates easy mixing and application.

Thickener:

HPMC acts as an effective thickener, imparting viscosity to adhesive formulations. This thickening property is critical to preventing the adhesive from sagging or slumping when applied to vertical surfaces.

Film forming ability:

HPMC has film-forming properties that form a protective film on the adhesive layer after drying. The film enhances the adhesive’s durability and water resistance.

Improve adhesion:

The presence of hydroxypropyl and methyl groups in HPMC enhances its adhesion to a variety of surfaces, making it an ideal ingredient in tile adhesives used to bond different substrates.

3.Uses of HPMC in ceramic tile adhesives:

Improved machinability:

HPMC provides a smooth, consistent texture that enhances the workability of the tile adhesive. This is especially important during the application of the adhesive to ensure an even and reliable bond between the tile and the substrate.

Water retention:

HPMC helps retain moisture in adhesive formulations, preventing premature drying. The extended open time allows for proper positioning of tiles before the adhesive sets, especially on large tile projects.

Reduce shrinkage:

Shrinkage can be a problem in adhesive formulations. HPMC alleviates this problem by reducing the overall shrinkage of the adhesive during drying, ensuring a stable and long-lasting bond.

Enhanced flexibility:

Tile adhesives containing HPMC are more flexible and can accommodate small movements or expansions of the substrate. This flexibility is critical to preventing cracks in the adhesive layer and tile surface.

4. Advantages of using HPMC in tile adhesives:

Consistent performance:

HPMC helps maintain consistent tile adhesive performance, ensuring reliable bonding under varying environmental conditions.

Versatility:

The versatility of HPMC allows it to be used in a variety of formulations to meet specific requirements such as rapid setting, extended open time or enhanced adhesion.

Water resistance:

The film-forming ability of HPMC enhances the water resistance of tile adhesive, making it suitable for use in wet areas such as bathrooms and kitchens.

Easy to apply:

The water-soluble nature of HPMC simplifies the mixing and application process, making it convenient for professionals and DIYers alike.

Hydroxypropyl methylcellulose (HPMC) is an important ingredient in tile adhesives, helping to improve their overall performance and effectiveness. Its unique properties, including water solubility, thickening ability, film-forming ability and improved adhesion, make it ideal for enhancing the performance of tile adhesives. As the construction industry continues to evolve, HPMC remains a key player in adhesive formulations that meet the needs of modern construction projects.